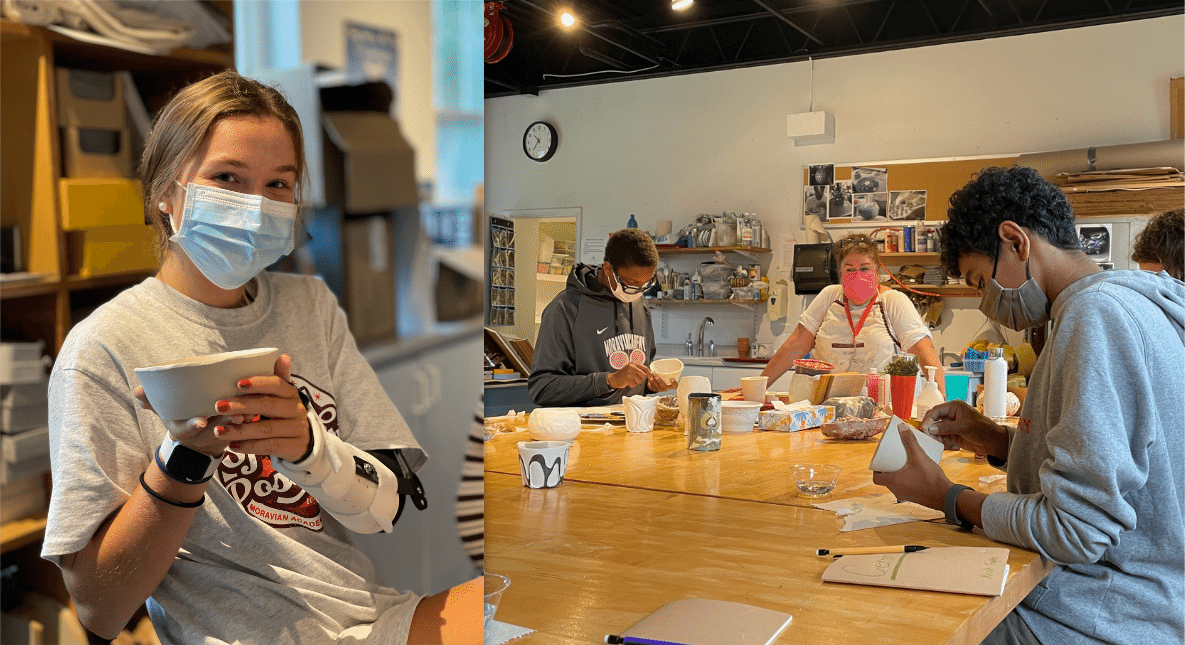

Slip Casting in Ceramics 1

We began the year pouring porcelain slip casts to dry to the leather hard stage so as to "alter" the surface so that they are other than smooth.

These surface techniques will provide for future layers of glazes to break and puddle which offers amazingly interesting results! Pictured left, Ben Edelman '23 pours porcelain into the mold. Kendall Bolden '23 works in the background.

These surface techniques will provide for future layers of glazes to break and puddle which offers amazingly interesting results! Pictured left, Ben Edelman '23 pours porcelain into the mold. Kendall Bolden '23 works in the background.

Once the liquid porcelain slip is poured into the plaster molds, the moisture is absorbed from the slip up against the plaster surface and within 30-40 minutes creates a thick "skin" which eventually will be the walls of the clay form.

The slip not hardened in the center is poured out. The follow-up shrinkage which occurs will allow for the form to be easily popped out and removed from the plaster mold. (With these one-part molds, the original must be created with no "undercuts" and will most likely be destroyed in the process.)

This week, students removed the porcelain from the molds and began refining the shape and texture.

While the clay is still malleable it can easily be carved, gouged and/or pieced into so the incisions achieve a surface that has a variety of levels showcasing the amazing qualities of the glazes the student have selected. In addition, students will apply a resist material and use a "water erosion" technique wiping away the unprotected clay to create other low relief surface changes. The combo of these techniques and the myriad of glaze choices available provides an almost limitless amount of options for these young artists!

Above, Grace Burcaw '22 proudly displays her progress so far.

myMA

myMA